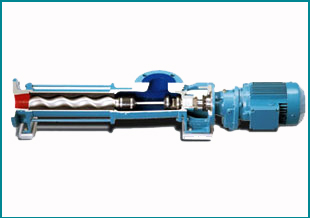

Description

This is a type of positive displacement pump and the working principle is based on Archimedes Screw.

Typical Pumped Media

Effluent with & without solids, Milk of Lime, General Sewage Slurry, Media, Protective Chemicals, Acids, Adhesives, Caustic Soda, Cellulose, Cement Slurry, Dye Liquor, Dye Baths, Flouring, Plaster, Grout, Ink, Mortar, Coal Slurry, Lime Slurry, Colors, Cosmetics, Detergents, Glue, Lacquers, Hair Oil, Hand Washing Cream, Paints, Shampoos, Waxes, Alcoholic Beverages, Apple Puree, Baby Food, Beer, Beet Sludge, Biscuit Dough, Citrus Fruit Masher, Cream Cheese, Edible Oil, Eggs, Raw Fats, Fish Residues, Fruit & Berry Masher, Honey, Ice Cream, Lard, Meat Extract, Milk, Mustard, Tomato Paste, Vegetable Oil, Wine, Yeast.

Salient features

- Sturdy drive design provides strength for rigorous continuous operation.

- Unique pivot-joint design extends service life and reduces replacement cost.

- Close coupled models with built-on speed reducers offer compact pumping unit.

- Stators are available in a wide range of elastomers.

- Special ES version with rugged torque transmitting ability